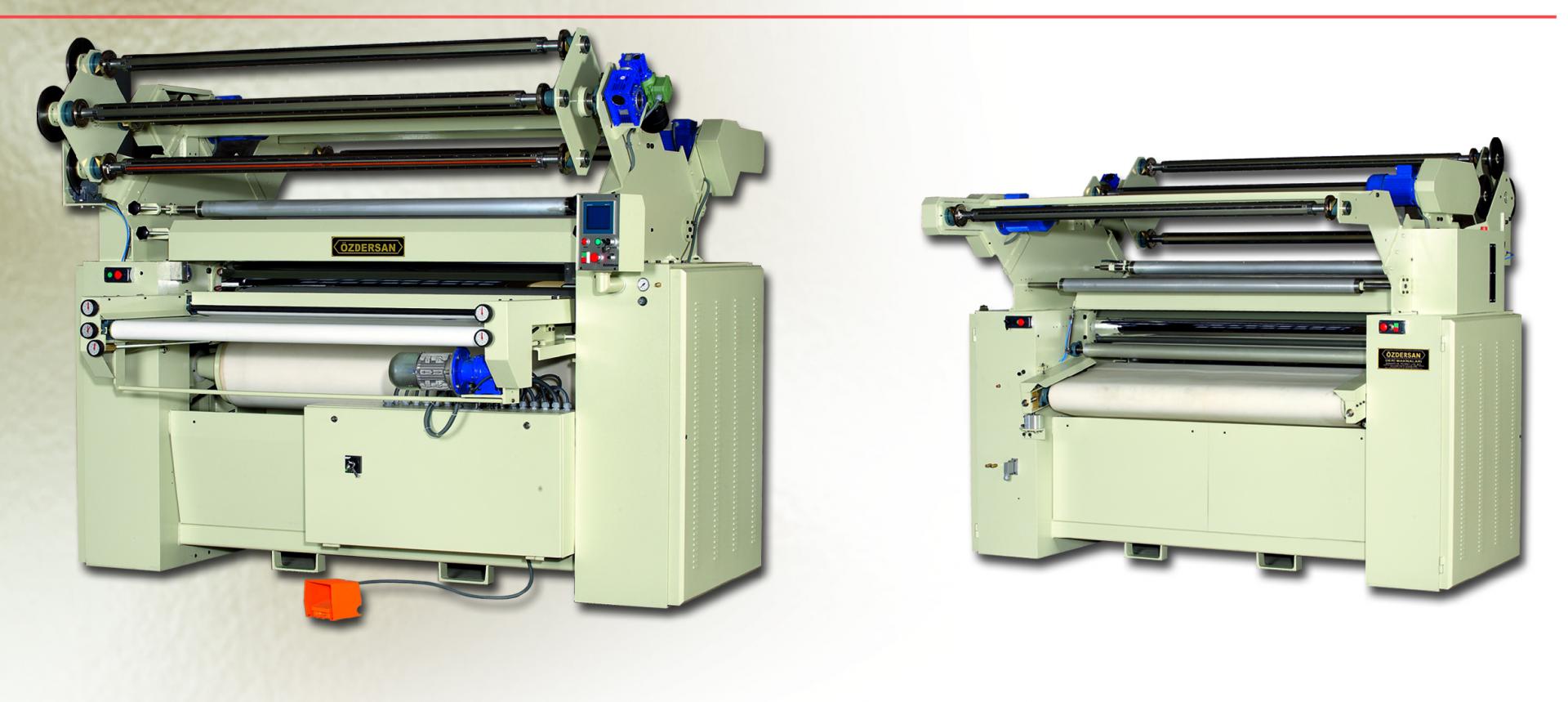

OUR PRODUCT TRANSFER FOIL MACHINE EASILY PRODUCED FOR THE APPLICATION OF FILMS ON LEATHER OR ON OTHER BASE MATERIALS (IMITATION LEATHER, TEXTILES, SYNTHETICS, ETC.), ALSO IT CAN BE USED FOR OTHER PARTICULAR TYPES OF MATCHING. THE MACHINE IS EQUIPPED WITH FULLY DIGITAL CONTROLS THAT ALLOW AN EASY ADJUSTMENT OF THE ALL WORK PARAMETERS (DEPENDING ON THE MATERIALS THAT ARE TO BE TRANSFERRED). ADDING THAT THE ADVANCED AND INNOVATIVE HYDRAULIC MECHANICS ALLOW TO OBTAIN UNEQUALLED RESULTS, WITH A VERY EFFICIENT VERSATILE AND SILENT WORKING SYSTEM. BESIDES, THE ROLLERS ARE REALIZED IN PARTICULAR MATERIALS.

AS AN OUR STANDARD, WE HAVE BEEN PRODUCING MACHINE WITH 4 ROLLERS FOR RAPID WORKING CONDITIONS. WHILE WE WERE DESIGNING MACHINE, WE FOCUSED ON MINIMIZING THE CUNSUMPTIONS OF PAPER AND TEMPERATURE. SO WE HAVE BEEN USING SPECIAL REZISTANCES FOR WARMING THE MAIN ROLLER ON OUR MACHINES FOR PREVENTING THE ELECTRICAL EXPENSES.

THE MACHINE IS EQUIPPED WITH FULLY DIGITAL CONTROLS (PLC) THAT ALLOWS ADJUSTMENT OF ALL THE WORK PARAMETERS BY TOUCH SCREEN, ALLOWS ADJUSTMENT OF MECHANICS, HYDRAULIC AND HEATING, AS HIGHLY SENSITIVE (DEPENDING ON THE MATERIALS THAT ARE TO BE TRANSFERRED). IT IS POSSIBLE TO MONITOR USAGE OF FILMS ON THE MACHINE AS PLC DIGITAL SCREEN.

BY THE WAY, ON THE MACHINE WE HAVE BEEN USING ANTI-STATIC BELTS FOR PREVENTING THE CLINGING OF THE PAPER. BY USING THAT KIND OF HIGH QUALITY BELTS FOR INCREASING THE SOFTNESS AND STICKINESS OF THE FOILS.

MISSION OF THE MACHINE

THE MACHINE IS USED FOR PROCESSING VARIOUS FABRIC AND LEATHER MATERIAL BY PRESSING STRETCH FILM AND PATTERN PRINT IN CONTINUATION.